wire edm machine how it works

Nowadays it is very common for large machining companies to use EDM to manufacture their parts. An electrical discharge machine.

How Does Wire Edm Work Laszeray Technology Llc

The EDM wire is tinymeasuring only 0010 to 0012and it may be made of brass or other materials for specific applications.

. A wire EDM machine looks like a bandsaw that has a wire for a blade. In wire EDM machining the material is removed from the workpiece by a series of rapidly recurring current discharges between the wire or the electrode and the workpiece they are separated by a dielectric liquid. Wire EDM happens through a tiny electrode in the shape of a wire.

A water jet or air jet guides the wire through the work piece. In Wire EDM a thin wire is used to cut the work piece. As the spark jumps across the gap material is removed from both the workpiece the electrode.

During the machining the wire is constantly coming from an automated feed with a spool. How It Works. To begin the cut the wire must cut into the metal from the side or through a hole that is drilled into the center of the metal.

Both the workpiece and the wire are submerged in the dielectric fluid. In EDM machine the material is removed by rapidly recurring repeating discharges of current in between the. The type of electrical discharge machining EDM Machine Inc.

A water jet or air jet guides the wire through the work piece. The metal that needs to be cut is submerged in deionized water and the spool of wire is charged with electricity. MC Machinery can update your machinery eliminate bottlenecks and drive throughput.

Wire EDM machining also known as spark EDM works by creating an electrical discharge between the wire or electrode the workpiece. To stop the sparking process from shorting out a non conductive fluid or dielectric is also applied. The wire is threaded through the hole to start.

Wireworks Edm - Manufacturers Factory Suppliers from China With a positive and progressive attitude to customers curiosity our organization repeatedly improves our products top quality to meet the wants of consumers and further focuses on safety reliability environmental necessities and innovation of Wireworks Edm Hydraulic Cylinder. Increase capacity and reduce overhead. Ad Choose from a variety of Wire EDM machines.

Wire EDM is machining using an electrical discharge. Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes. In this case the wire works as the electrode.

The full name for the device is a Wire-cut Electrical Discharge Machine The wire in this case is a long spool of very thin coated brass wire. Wire EDM uses an electrically charged strand of wire fed from a reel and moved through upper and lower guides. The wire is energized as it passes across a power contact at the top and bottom.

This can be done with a conventional drill or with an EDM drilling machine. This EDM process doesnt technically cut material it melts or vaporizes it leaving little debris and providing a very accurate line. Modern wire EDM machines provide automatic threading.

The wire electrode is consumed during the process but is continuously. If the wire breaks while cutting a part the machine senses the break re-threads the wire and resumes the cut where the wire broke. EDM is used industry-wide and do to its versatility is relied upon.

The machine automatically makes the necessary mechanical and electrical connections. Electrical Discharge Machining EDM is a non traditional machining and electro thermal process in which material from the workpiece is removed by using electrical discharges sparks. Basic introduction to the wire EDM and high-speed small hole EDM processes.

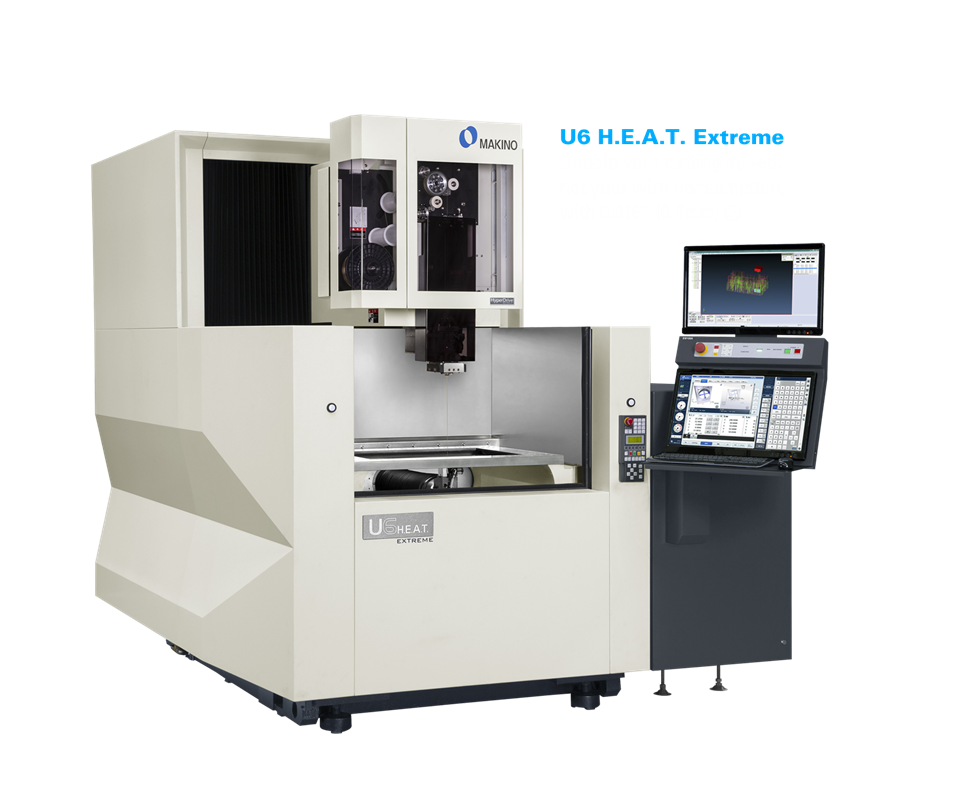

He was an English physicist. He machine is built on the proven Makino Uj-Series Wire EDM platform that utilizes a stationary table design and is held to an even higher construction accuracy specification. A non-conventional process though hardly a new one wire EDM works on parts resistant to conventional machining processes but only if these parts are electrically conductive.

Wire Edm Cutting Speed Table - Manufacturers Suppliers Factory from China Our business sticks for the basic principle of Quality could be the life with the firm and track record will be the soul of it for Wire Edm Cutting Speed Table Industrial Boring Machine Small Cylinder Hone Manual Boring Machine Horizontal Boring Machine. The spark takes place in deionized water. It shoots tiny lightning bolts through a water or oil insulator called a dielectric using electrical energy to blast away tiny bits of metal.

A wire EDM machine uses a thin piece of electrically charged wire as a saw blade to cut any metal which will conduct electricity. How Wire EDM Works. The machine automatically makes the necessary mechanical and electrical connections.

The distance between the guides can be adjusted to accommodate the thickness of the workpiece. Wire EDM can easily cut hard conductive material and produce complex parts with high precision. A wire EDM machine is a type of CNC machine that can move along four independent axes to generate taper cuts.

The UPV-3 Wire EDM machine was designed to produce the ultimate in precision machining while achieving ultra-fine surface finishes. It was first observed in 1770 by Joseph Priestley. Electrical discharge machining EDM also known as spark machining spark eroding die sinking wire burning or wire erosion is a metal fabrication process whereby a desired shape is obtained by using electrical discharges sparks.

Uses is commonly known as wire manufacturing wire burning or wire erosion. How important is it for creating pieces. This spool can be up to nearly 12 miles long.

For example a stamping die can be machined with 14 degree taper or a mold with one degree taper in some areas and two degrees in another with precision. Short interesting video on the fundamentals of the electrical discharge machinin. Your Wire EDM machine uses a thin electrically conductive wire generally brass as an electrode to cut the workpiece to create the desired profile or shape.

It is controlled by a state-of-the-art computer as well as being able to guide you to the correct points to be cut. Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece. The second type of electrical discharge machining is called wire EDM and is also known as wire erosion wire burning or spark EDM.

Usually they are non-ferrous and. Modern wire EDM machines provide automatic threading. Simply put you can think of wire EDM as a highly accurate bandsaw one with a blade wire measuring 0010 or so in diameter.

Structure Characteristics Of Cnc High Speed Wire Cut Edm 1 Kingred Electrical And Mechanical Technology Co Ltd

Wire Electric Discharge Machining Wire Edm Youtube

News Brass Wire For Wire Cut Machine Die Sinking Electrical Discharge Machine Fully Automatic Wire Cutting Machines Novick Digital Equipment Co Ltd

Wire Edm Machining Wire Cutting Services In China

How Wire Edm Works Missouri S Wire Edm Machine Shop

What Is Wire Edm A Guide To Wire Electrical Discharge Machining